Title: New Optimal Design Tools for Future Wind Turbine Blades

Funding from: Det Fri Forskningsråd – Individual Postodoc Grant

Amount: 1.4 million Danish Kroner

Duration: 1st of June 2013 through 31st of May 2015

Description: The object of this project is to develop and study new methods for optimal structural and aerodynamic design of wind turbine blades based on topology optimization techniques. The ability to reduce the cost of wind energy through an increase in the size of wind turbine rotor blades has motivated the ongoing trend of "bigger is better". However, as the size of wind turbine blades increases new structural and aerodynamic design challenges emerge, e.g., self-weight and gravity induced fatigue damage. Addressing these issues has become a cornerstone for the realization of larger wind turbine blades. This project suggests the development and study of new numerical optimization tools for wind turbine blade design to specifically tackle these new challenges. Achieving to do so will render the design of larger wind turbine blades feasible and consequently allow for the continuing reduction in the cost of wind energy.

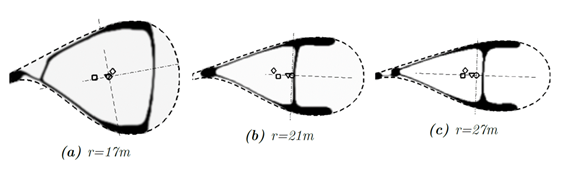

Figure above: Structural topology optimization of wind turbine blades for additive manufacturing using BECAS.